Understanding pit lake water quality is critical to operational management and especially closure planning.

Why do we need to know pit lake water quality?

Pit lake water quality defines both the current and future risks of pit lakes; as well as what opportunities e.g., repurposing, they might afford to stakeholders.

However, many people are still sampling of pit lakes from the edge and surface, which completely ignores the typical water quality differences these deep lakes experience through their deep water columns (McCullough et al. 2011). Hence, a water sample taken from the upper even 1.0 m may completely misrepresent the deeper 98% of a mere 50 m deep water column!

Water quality changes substantially from the surface down through a pit lake’s water column.

Many mining companies and their consultants may also be unaware, but using a boat for sampling water quality requires the operator to be commercially qualified with a minimum Coxswain Grade 2 (Restricted Coxswain) marine license. OSH issues working over very deep water from a small and unstable vessel should also be considered with a Safe Work Method Statement (SWMS) guidance tool prepared prior to boat use, although worker liability will remain if operators are not accredited as operators. MLC staff are experienced and endorsed with commercial vessel licences.

But even though we can (and do!) fly our inflatable boats anywhere in Australia (bar some puzzled looks from airline staff with boats going onto charter flights to desert regions) pit lake sampling often means access is too difficult or dangerous for boats to enter an unstable mine void (Ross & McCullough 2011).

How do we sample pit lakes?

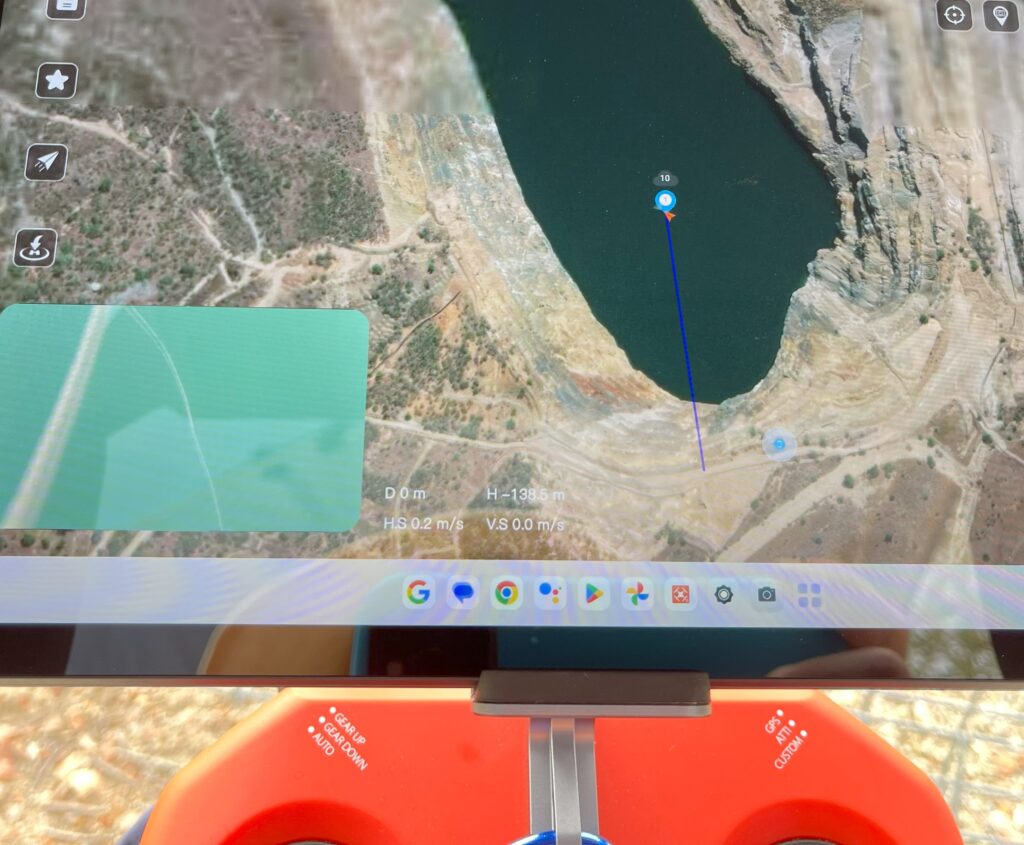

As a result, MLC has developed and regularly undertakes leading international pit lake water sampling by UAV (drone).

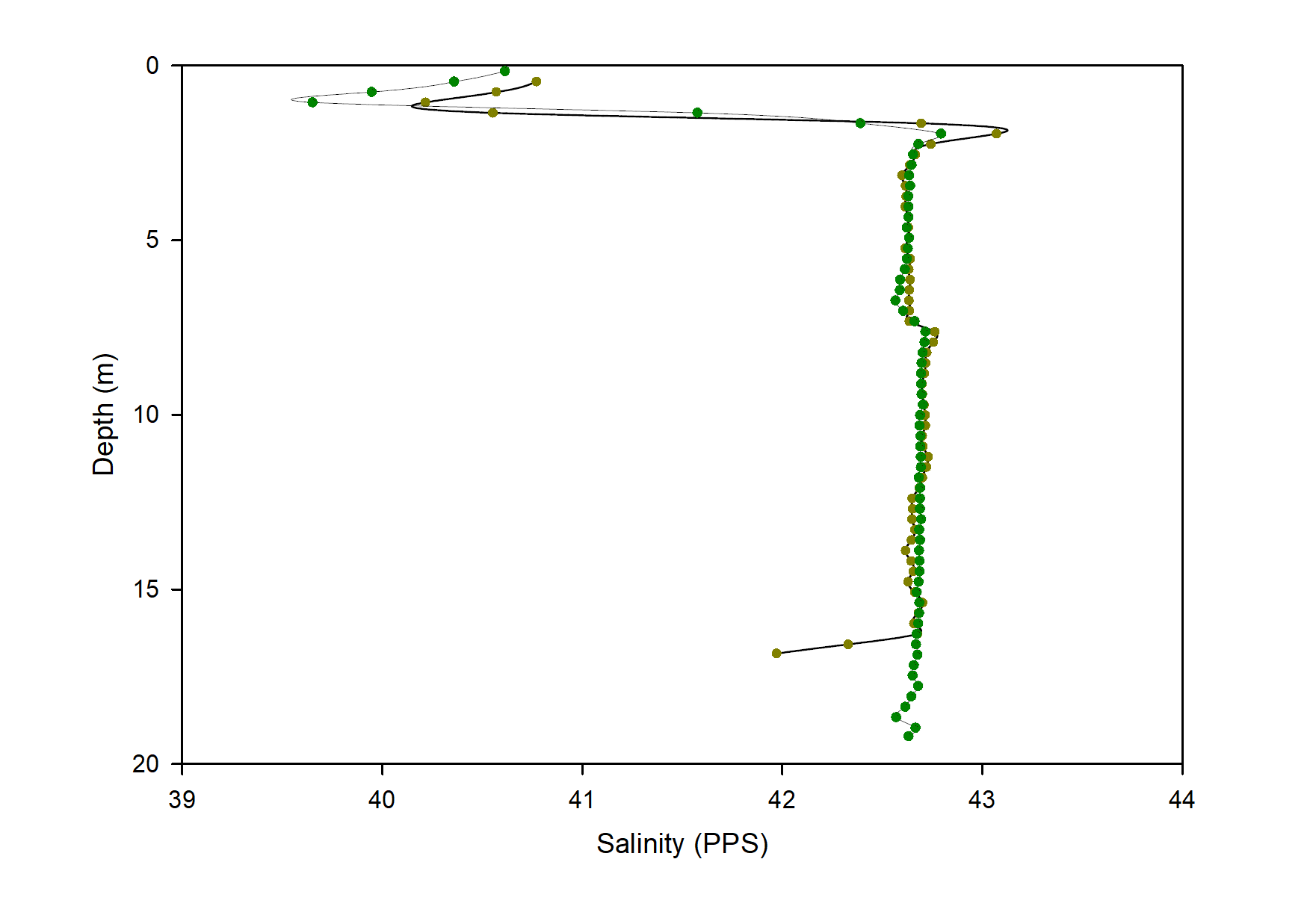

Safe behind either a highwall bund or on a lake shore, we characterize the entire salinity and temperature of the mine lake first (Gammons & Tucci 2011). Searching for physico-chemical fingerprints of thermal and chemical stratifications (thermoclines and chemoclines respectively). Then our drones literally fly water from the bottom of a 50 m+ pit lake back to our very hands.

We use proprietary MLC-designed samplers with double-locks to preserve sample depth integrity, even from pit lakes as deep as 100 m. These samplers are customised to the needs of the specific analyte suite we are targeting. Sample depth is similarly targeted to pre-identified stratification.

We also use a proprietary MLC-designed spool line deployment system that reduces take-off height to no more than a few metres and considerably saves on battery power to the pit lakes’ surface, in addition to reducing safety to persons and property from excessive sampler line during UAV take-off and travel to the lakes’ surface.

Our drones will even land on the water’s surface, power down, and wait for the sampler to fill before safely then returning back to their landing pads automatically, under the control of GP, RF and barometric sensors.

Although we prefer visual line of sight (VLOS), on-drone 3-gimbal, 4K cameras also provide more flight information to our fully qualified and CASA certified UAV pilots. We use additional spotters to extend operations to beyond visual line of sight (BVLOS) where further safety requirements are needed.

Used correctly, drones offer a high-resolution alternative to boat-based pit lake water column profiling.